Understanding the importance of installation

The MDVR Truck Management System is more than just a set of cameras or GPS trackers—it is a comprehensive platform designed to enhance fleet safety, efficiency, and accountability. For cargo and delivery companies, successful installation determines whether the system delivers reliable monitoring, secure data access, and improved compliance. A properly installed MDVR Truck Management System ensures managers can view live footage, track vehicle routes, and review alerts in real time. This capability reduces risks such as theft, accidents, and regulatory violations. Investing the right amount of time and attention in the installation stage sets the foundation for all the long-term benefits this system brings.

Pre-installation preparation

Assessing fleet requirements

Before installing an MDVR Truck Management System, managers must evaluate fleet needs carefully. This includes determining how many cameras are required per vehicle, whether forward-facing, rear-facing, or cabin cameras are necessary, and what kind of data storage capacity will be sufficient. An accurate assessment ensures the system is tailored to the business rather than over- or under-equipped.

Preparing tools and workspace

Installation success depends heavily on preparation. Having the correct tools, from mounting brackets to secure wiring kits, is essential. Vehicles should be positioned in clean, well-lit areas to avoid interruptions. Ensuring a safe and organized environment prevents errors during installation and speeds up the process. With preparation in place, the MDVR Truck Management System can be installed smoothly and efficiently.

Step-by-step installation process

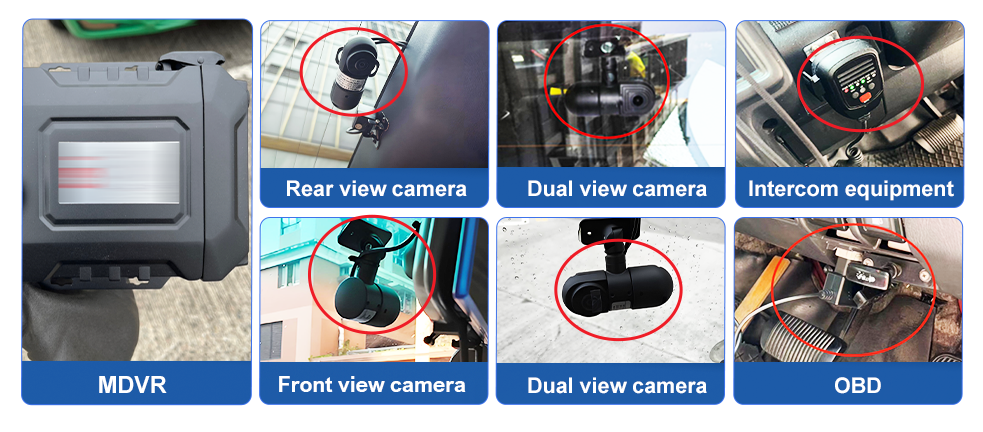

Mounting cameras securely

The core of an MDVR Truck Management System lies in its camera units. These must be mounted in stable positions to capture the required footage without vibration or obstruction. Placement is critical: forward cameras monitor the road, side cameras record blind spots, and cabin cameras track driver behavior. Secure mounting guarantees clear footage and reduces the risk of equipment damage during vehicle operation.

Wiring and power connection

Wiring is the backbone of the MDVR Truck Management System. Cables must be routed neatly through protective channels to prevent wear and interference. Power connections should be double-checked for stability to ensure cameras and recorders remain active during all trips. A reliable wiring setup guarantees uninterrupted data capture and minimizes technical failures over time.

Tips for faster and safer installation

Coordinating with trained staff

While installation manuals provide step-by-step instructions, having trained staff available significantly speeds up the process. Experienced technicians are familiar with potential pitfalls and can solve problems quickly. For businesses installing multiple MDVR Truck Management Systems across large fleets, professional coordination ensures consistency and efficiency.

Following safety protocols

Safety during installation cannot be overlooked. Electrical wiring, drilling, and equipment mounting pose risks if handled carelessly. Following safety protocols such as disconnecting vehicle batteries before wiring, wearing protective gloves, and securing ladders during camera mounting is essential. Prioritizing safety avoids accidents and ensures smooth project completion.

Common challenges and solutions

Managing compatibility issues

Not every vehicle type is the same, which means MDVR Truck Management System compatibility can vary. Older trucks may lack convenient wiring paths, while newer models may require specific adapters. By planning ahead and reviewing compatibility requirements, managers reduce delays and ensure systems function optimally across diverse fleets.

Avoiding connectivity errors

Cloud access is a vital feature of the MDVR Truck Management System, but it relies on stable connections. Poor SIM card coverage or incorrect configurations can cause interruptions. Managers must test network reliability and confirm proper SIM installation. Addressing connectivity issues during setup guarantees reliable data uploads and real-time monitoring.

Post-installation testing and optimization

Verifying system functionality

Once an MDVR Truck Management System is installed, testing becomes a critical step. Managers and technicians must verify that every component is working as intended. This includes checking live video streams from all cameras, confirming GPS accuracy, and reviewing cloud uploads. By running test drives, teams can simulate real scenarios and confirm that alerts, notifications, and data transfers are reliable. Thorough verification ensures that the system performs correctly under daily operations and minimizes future disruptions.

Calibrating settings for managers

The true value of the MDVR Truck Management System lies in how well it is calibrated for managerial needs. Managers can set parameters for alerts, such as speeding, sudden braking, or route deviations. Fine-tuning these settings makes the system more responsive and aligned with operational goals. Additionally, administrators can adjust storage preferences, deciding how long data should be retained on cloud servers. These settings turn the system into a powerful management tool rather than just a recording device.

Maintenance and long-term reliability

Regular inspection and cleaning

Like any advanced electronic solution, the MDVR Truck Management System requires ongoing care. Cameras should be inspected regularly for dust or obstruction, and cables must be checked for wear. Performing scheduled inspections prevents small issues from escalating into system failures. By investing time in regular maintenance, managers extend the lifespan of the system and ensure consistent performance across the fleet.

Software updates and manual optimization

Unlike some automated solutions, the MDVR Truck Management System does not learn by itself. Updates and improvements rely on manual code optimization. Technicians must install firmware updates, patch vulnerabilities, and enhance features over time. This manual process ensures the system remains secure, up to date, and capable of meeting evolving compliance requirements. For managers, keeping the software current is as important as maintaining the hardware, guaranteeing reliability year after year.

Downloadable resources

Access to manuals and documentation

For businesses managing multiple installations, having access to clear manuals and documentation is vital. The MDVR Truck Management System includes detailed guides that outline every step of the process. These documents serve as valuable references for technicians and managers, ensuring consistency and reducing the likelihood of mistakes.

Video tutorials for visual learning

Some teams benefit more from visual instructions. Video tutorials demonstrate the installation process step by step, making it easier for new staff to understand complex tasks. By combining manuals with video resources, businesses ensure that every technician has the support needed to successfully install and maintain the MDVR Truck Management System.

FAQs

How long does it take to install an MDVR Truck Management System

Installation time depends on the complexity of the vehicle and the number of cameras required. On average, a single truck installation can be completed within half a day, while larger fleets may require coordinated schedules to finish efficiently.

Can managers access video and data remotely

Yes, the MDVR Truck Management System provides cloud-based access. Managers can log in securely to review live video, GPS locations, and stored data from any device, ensuring full oversight even when away from the fleet.

How does the system help with driver accountability

By recording driver behavior and integrating features such as DMS, the MDVR Truck Management System ensures that every action can be reviewed. This helps managers educate drivers, assign responsibility in case of incidents, and enforce consistent standards across the fleet.

Why is regular maintenance important

Regular maintenance ensures the system continues operating reliably. Cleaning cameras, checking wiring, and updating software prevent failures and extend the service life of the MDVR Truck Management System, ultimately protecting the company’s investment.